THE BREWERY

138 N. MOUND STREET, NACOGDOCHES, TX

This is how

OUR BEER GETS BREWED

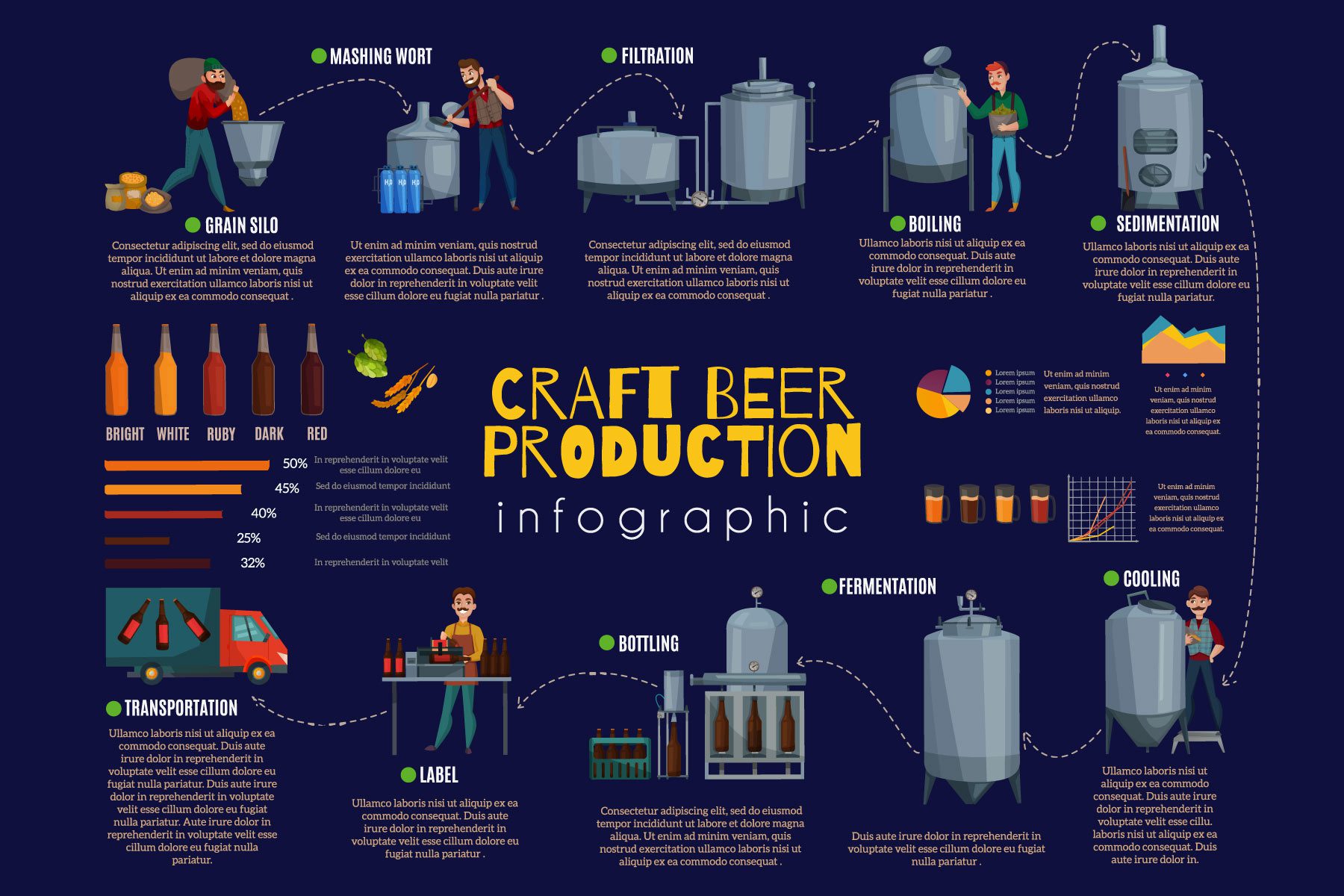

At Fredonia Brewery, all of our production and packaging equipment comes from our friends at American Beer Equipment in Lincoln, NE. Our production team uses our four-vessel, 15-barrel brewhouse (in brewing, one barrel equals 31 gallons) to create the “wort” (sweet liquid) that is the first stage of the brewing process. This part of the process takes roughly 10 hours.

The wort is then transferred to one of the vessels in our 195-barrel cellar, where yeast is introduced. Over the next 2-4 weeks, the yeast converts the sugars in the wort into alcohol. At the end of this step, the temperature in the tank is lowered to help clarify the beer.

Finally, the flat beer is moved to our 30-barrel brite tank, where it is carbonated. Once the beer is ready, our packaging team fills the waiting cans and kegs, and then it’s ready to enjoy!

Interested in a tour? Our bar staff love to show off our brewhouse and cellar to guests. Ask at the bar, and if we’re not too busy, we’ll show you around! If you want to schedule a Tour and Tasting Experience, email [email protected]!

The Brewing

Process

Have a question about the brewery?